How I Improved My Welding Projects Using Anti Spatter Spray: An Expert’s Perspective

When I first started welding, one of the most frustrating challenges I faced was dealing with the stubborn spatter that would cling to my workpieces, tools, and equipment. It not only made the finished product look messy but also added extra time and effort to the cleanup process. That’s when I discovered the game-changing benefits of Anti Spatter Spray Welding. This simple yet powerful solution has transformed the way I approach welding, helping me achieve cleaner results and save valuable time. In this article, I want to share why anti spatter sprays have become an essential part of my welding toolkit and how they can make a difference for anyone working with welds.

Weld-Aid Weld-Kleen Heavy Duty Anti-Spatter Liquid, 20 Wt Oz, Paintable, Non-Flammable, Quick Drying Aerosol Spray

Akfix A90 Anti Spatter Welding Spray (1×12 Oz.) – Heavy Duty Welding Anti-Spatter Spray for Arc, MIG and TIG tips, Non-Flammable Anti Splatter Welding Spray for Safe Welding | 12 Oz. 1 Pack

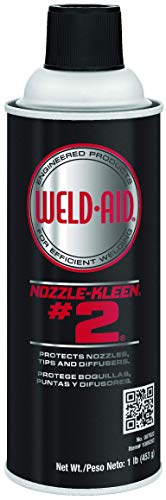

Weld Aid Nozzle-Kleen 2 007022 – 16 wt. oz., Non-Flammable, Paintable Anti-Spatter Aerosol Spray for MIG, TIG Tips, Weldments

Kraken Bond Anti Spatter Welding Spray – (2x12oz) Anti-Splatter Aerosol Spray for MIG, TIG Tips, Protects Surfaces & Materials, Non-Flammable, Safe for Workpieces and Jigs, 2 Pack

1. Weld-Aid Weld-Kleen Heavy Duty Anti-Spatter Liquid, 20 Wt Oz, Paintable, Non-Flammable, Quick Drying Aerosol Spray

When I first came across the Weld-Aid Weld-Kleen Heavy Duty Anti-Spatter Liquid, I was immediately drawn to its promise of being a heavy-duty, non-flammable, quick-drying aerosol spray. As someone who frequently works with welding equipment, I understand how crucial it is to have a reliable anti-spatter spray that not only protects my tools but also enhances the efficiency of my workflow. The fact that this product is paintable adds another layer of versatility, allowing me to maintain the appearance of my workpieces without worrying about residue or damage.

One of the standout features of this Weld-Kleen spray is its heavy-duty formulation combined with a non-flammable base. This means I can safely use it in high-temperature environments and even during pre-heating processes without the risk of fire hazards. The quick-drying nature of the aerosol is a significant advantage because it minimizes downtime. I don’t have to wait long after application before I can resume welding, which is essential when working on tight schedules or with higher duty cycles.

The excellent protection offered by this formula is something I truly appreciate. Welding tools and fixtures often suffer from spatter buildup, which can lead to increased cleaning time and potential damage. Using this product helps keep my tools and workpieces clean, thereby reducing the need for frequent maintenance and minimizing interruptions. In my experience, this leads to better overall productivity and less frustration during long welding sessions.

Another aspect that makes the Weld-Kleen spray highly practical is its wide range of applications. Whether I’m working with resistance welding tips, MIG or TIG tips, weldments, electrode holders, or even metal molds and bench top splash guards, this spray has proven effective. This versatility means I only need one reliable anti-spatter solution for multiple tools and surfaces, which simplifies my inventory and ensures consistent protection across the board.

To give a clearer picture, here’s a summary table of the product features and what they mean for me as a user

Feature Benefit Heavy Duty Anti-Spatter Spray Provides robust protection even in demanding welding environments. Non-Flammable Safe to use during pre-heat and high temperature applications without fire risk. Quick Drying Aerosol Minimizes downtime by allowing faster resumption of work after application. Paintable Allows for finishing without compromising the weld area appearance. Wide Application Range Suitable for multiple tools and surfaces, reducing the need for multiple products. 20 Wt Oz Aerosol Can Provides a convenient, easy-to-use format with a good quantity for extended use. Weld-Aid Engineering Designed specifically to enhance welding efficiency and tool longevity.

In summary, the Weld-Aid Weld-Kleen Heavy Duty Anti-Spatter Liquid ticks all the boxes for me. It’s a well-thought-out product engineered to improve the welding experience by protecting my tools, reducing cleaning time, and enabling faster project completion. If you’re looking for a dependable, safe, and efficient anti-spatter spray, this product is definitely worth considering. It has become an essential part of my welding toolkit, and I believe it can do the same for anyone serious about maintaining their equipment and optimizing their workflow.

Get It From Amazon Now: Check Price on Amazon & FREE Returns

2. Akfix A90 Anti Spatter Welding Spray (1×12 Oz.) – Heavy Duty Welding Anti-Spatter Spray for Arc, MIG and TIG tips, Non-Flammable Anti Splatter Welding Spray for Safe Welding | 12 Oz. 1 Pack

When I first came across the Akfix A90 Anti Spatter Welding Spray, I immediately recognized its potential to make my welding projects much smoother and cleaner. The product title itself highlights that this is a heavy-duty, solvent-based anti-spatter spray, designed specifically for Arc, MIG, and TIG welding tips. As someone who frequently works with all three welding types, having a reliable anti-spatter solution is crucial, and this spray promises to deliver exactly that. The fact that it is non-flammable adds a significant safety factor, which I personally value highly during intense welding sessions.

One of the standout features I noticed is its heavy-duty solvent base. This means it offers robust protection against welding spatter, which can often be a major headache by causing buildup on tips and surrounding areas. By keeping my workspace clean and free of spatter, I can focus more on precision and quality in my welds rather than spending extra time on cleanup. This not only improves workflow but also enhances the overall efficiency of my welding operations.

The versatility of the Akfix A90 spray is another aspect that really appeals to me. Whether I’m working on a professional job or just a hobby project, this product is optimized for all welders and welding scenarios. It’s comforting to know that no matter the complexity or type of welding I’m doing, this spray can assist in producing clean, precise results. The ease of application is a bonus—just spray it on and get to work. The aerosol form makes it incredibly convenient to apply evenly and quickly, which I find essential for maintaining productivity.

Safety is always top of mind, and this anti-spatter spray’s non-flammable nature reassures me that I can use it confidently without worrying about ignition risks during high-temperature welding. After the solvent evaporates, the protective layer remains without posing any fire hazards. This peace of mind allows me to focus fully on the welding process rather than second-guessing the safety of my materials and environment.

From a practical standpoint, the Akfix A90 is incredibly versatile. It’s not just for protecting the welding tips but also keeps tools, nozzles, torches, workpieces, and even welding robots spatter-free. This broad range of applications means it’s a one-stop solution for maintaining the cleanliness and longevity of all my welding equipment. Such comprehensive protection helps enhance the quality of the welds, reducing defects and rework.

Moreover, I appreciate how economical and efficient this spray is. By reducing downtime caused by cleaning and maintenance, it helps me save both time and operational costs. The extended tool life that results from preventing spatter buildup is a smart investment, especially when considering the expense of welding tips and nozzles. The industrial strength formula means it’s built to withstand the toughest environments, making it a reliable choice for anyone serious about welding.

Ultimately, I see the Akfix A90 Anti Spatter Welding Spray as a must-have for welders. It is designed to shield a wide range of welding equipment from the nuisance of spatter, making my welding process smoother and more efficient. The ease of use, safety features, and heavy-duty protection all come together to create a product that genuinely supports my welding work. If you’re looking to enhance the quality and safety of your welding tasks while saving time and money, this spray is definitely worth considering.

Feature Benefit to User Heavy Duty Solvent-Based Formula Provides strong protection against spatter, keeping workspace clean and tools protected Optimized for All Welders (Arc, MIG, TIG) Suitable for professionals and hobbyists, ensuring clean, precise welds every time Easy Aerosol Application Quick, convenient spray-on use saves time and effort during preparation Non-Flammable After Solvent Evaporation Enhances safety by eliminating fire risk during welding operations Versatile Use on Tools and Workpieces Protects a wide range of equipment, improving weld quality and tool longevity Economical and Efficient Reduces downtime and operational costs by minimizing cleaning and maintenance Industrial Strength Formula Durable enough for the toughest welding environments Get It From Amazon Now: Check Price on Amazon & FREE Returns

3. Weld Aid Nozzle-Kleen 2 007022 – 16 wt. oz., Non-Flammable, Paintable Anti-Spatter Aerosol Spray for MIG, TIG Tips, Weldments

When I first came across the Weld Aid Nozzle-Kleen 2 007022, I immediately recognized it as a thoughtfully engineered solution aimed at making welding tasks smoother and more efficient. As someone who spends a considerable amount of time working with MIG and TIG welding, I truly appreciate products that not only improve the quality of my welds but also save me time and reduce frustration. This 16 wt. oz. aerosol spray stands out because it is specifically designed to prevent spatter buildup on nozzles and tips, which is a common issue that can disrupt workflow and compromise weld quality.

One of the key advantages I noticed is that this spray is both non-flammable and paintable. This means I can use it confidently around hot metal surfaces without worrying about fire hazards, which adds an essential layer of safety in my workspace. The paintable feature is also a nice touch because it allows me to maintain the appearance of my equipment without leaving unsightly residues. This product’s dual role as both a cleaner and a lubricant really impressed me, as it helps maintain the longevity and performance of welding tips and related components.

In terms of application, the Weld Aid Nozzle-Kleen is incredibly versatile. I have used it not only on MIG and TIG tips but also on electrode holders, contact tips, and even metal molds. Its effectiveness across these various uses means I don’t have to juggle multiple products, which streamlines my tool kit and reduces costs. What I found particularly beneficial is how it creates less smoke and odor compared to other anti-spatter sprays I’ve tried. This makes the welding environment more pleasant and safer for prolonged use.

Another important feature that stood out to me is the quick-drying technology. After a light spray application, I can begin welding almost immediately without waiting for long drying times. This quick turnaround helps reduce downtime and keeps projects moving efficiently. When it’s time to clean up, the spatter wipes away effortlessly, saving me from the tedious and time-consuming task of scraping and grinding. The overall ease of use is a significant advantage, especially in busy work environments where every minute counts.

To give a clearer picture, here’s a summary table of the Weld Aid Nozzle-Kleen 2 features and benefits

Feature Benefit Non-Flammable Aerosol Safe to use around hot welding equipment, reducing fire risk Paintable Formula Maintains equipment appearance without residue buildup Prevents Spatter on Tips and Nozzles Improves welding quality and reduces downtime Quick-Drying Technology Allows immediate welding after application, saving time Low Smoke and Odor Creates a safer, more comfortable work environment Versatile Use Works on MIG/TIG tips, electrode holders, molds, and tools 16 oz. Aerosol Can Provides ample product for regular use with easy application Overall, I find the Weld Aid Nozzle-Kleen 2 to be an excellent addition to any welder’s toolkit. It addresses common welding hassles with practical, user-friendly features that enhance both safety and efficiency. If you want to reduce downtime caused by spatter buildup and improve the quality of your welds, this product is definitely worth considering. Its reasonable size and straightforward application make it a convenient and reliable choice. For anyone serious about welding performance and equipment maintenance, investing in this anti-spatter spray can pay off in time saved and better results.

Get It From Amazon Now: Check Price on Amazon & FREE Returns

4. Kraken Bond Anti Spatter Welding Spray – (2x12oz) Anti-Splatter Aerosol Spray for MIG, TIG Tips, Protects Surfaces & Materials, Non-Flammable, Safe for Workpieces and Jigs, 2 Pack

When I first came across the Kraken Bond Anti Spatter Welding Spray, I was immediately drawn to its promise of comprehensive protection and ease of use. As someone who spends a significant amount of time welding, whether using MIG or TIG techniques, I understand how frustrating welding spatter can be. It not only sticks to nozzles and workpieces but also increases cleanup time and sometimes affects the quality of the weld. Kraken Bond addresses these common issues head-on with its advanced formula that shields all surfaces in the welding area. This means that nozzles, tips, and the materials I’m working on stay cleaner, which directly improves the overall welding environment and workflow.

One feature that really stood out to me is the safety aspect of this spray. Welding environments can be intense and sometimes hazardous, so using a product that is non-flammable after the solvent evaporates gives me peace of mind. Whether I’m working in a manual setup or an automated welding cell, knowing that Kraken Bond is safe to use reduces worries about accidental fires or dangerous fumes. This safety-first design makes it an excellent choice not only for personal use but also for industrial applications where safety protocols are strict and compliance is essential.

Another big plus for me is its versatility. Kraken Bond isn’t limited to just one type of welding tool or process. Whether I’m using a handheld torch or a robotic welding arm, the spray applies seamlessly and performs consistently. This flexibility means I don’t need to purchase multiple anti-spatter products for different applications, simplifying my supply list and ensuring that every tool I use is well protected. Additionally, the spray’s ability to enhance tool longevity means fewer replacements and repairs, which is a cost-effective benefit over time.

The user experience is also thoughtfully considered. The aerosol spray dispenses smoothly and evenly, covering all necessary surfaces without any patchiness or excessive buildup. This ease of application saves time and reduces frustration, especially during long welding sessions. Whether I’m a professional welder or a hobbyist, the convenience of a product that works efficiently without a steep learning curve makes Kraken Bond a reliable addition to my welding toolkit.

Ultimately, the most compelling reason to use Kraken Bond is how it enhances weld quality. By minimizing spatter adhesion, it cuts down on the tedious cleanup process, allowing me to focus more on perfecting the weld itself. Cleaner surfaces mean fewer imperfections and a better final product, which is especially important when working on critical projects or professional jobs. Investing in this anti-spatter spray has noticeably improved my workflow and output quality, making it a worthwhile purchase that I would recommend to anyone serious about welding.

Feature Benefit Comprehensive Protection Prevents spatter adhesion on nozzles, tips, and workpieces, ensuring a cleaner welding area Non-Flammable Post-Evaporation Safe to use in intense welding setups, reducing fire hazards and increasing workplace safety Versatile Application Works effectively with manual torches and automated welding robots, enhancing tool longevity User-Friendly Aerosol Spray Applies smoothly and evenly, saving time and reducing application hassle Improves Weld Quality Minimizes cleanup and spatter, allowing focus on high-quality welds with less effort if you’re looking for a dependable, easy-to-use anti spatter solution that enhances safety, versatility, and weld quality, Kraken Bond Anti Spatter Welding Spray is a solid choice. The 2-pack format also offers great value, so you’ll have enough spray on hand for multiple projects. From my experience, this product not only meets but exceeds expectations, making it a smart investment for both professionals and DIY welders alike.

Get It From Amazon Now: Check Price on Amazon & FREE Returns

How Anti Spatter Spray Welding Has Helped Me

When I first started welding, dealing with spatter was one of the most frustrating parts of the process. Tiny molten droplets would stick to my workpiece and the welding nozzle, making cleanup a tedious and time-consuming task. Using anti spatter spray changed everything for me. It created a protective layer that prevented these droplets from adhering to surfaces, saving me a lot of effort after each weld.

Not only did the spray reduce cleanup time, but it also helped me maintain better weld quality. Without spatter buildup, my welding torch functioned more smoothly and consistently, which improved the precision of my welds. Plus, I noticed less wear and tear on my equipment since I wasn’t constantly scraping off hardened spatter.

Overall, anti spatter spray made my welding process more efficient and enjoyable. It allowed me to focus more on perfecting my technique rather than dealing with the mess, making it an indispensable part of my welding routine.

Buying Guide for Anti Spatter Spray Welding

Understanding Anti Spatter Spray and Its Importance

When I first started welding, I quickly realized how annoying welding spatter can be. These tiny droplets of molten metal stick to my workpiece and welding equipment, making cleanup a hassle and sometimes affecting the quality of my welds. That’s where anti spatter spray comes in. It acts as a protective barrier, preventing spatter from adhering to surfaces. Knowing this made me prioritize finding a good anti spatter spray early on.

Types of Anti Spatter Sprays

There are different formulations of anti spatter sprays available, such as water-based, silicone-based, and oil-based sprays. From my experience, water-based sprays are easier to clean and less messy, but sometimes need more frequent application. Silicone-based sprays offer strong protection but can leave residues that require solvents to remove. I had to consider these factors depending on how often I weld and how critical cleanliness was for my projects.

Application Methods

Most anti spatter sprays come in aerosol cans for easy application. I found that spraying the area just before welding gives the best results. Some sprays are designed for use on the welding tip or nozzle, while others are intended for the workpiece itself. It’s important to read the instructions carefully. In my case, I always made sure to apply a thin, even coat to avoid any interference with the weld pool.

Surface Compatibility

Not all anti spatter sprays work equally well on different metals or surfaces. When I was working on stainless steel, I noticed some sprays performed better than others. Always check if the spray is suitable for the materials you commonly weld, whether it’s steel, aluminum, or other alloys.

Health and Safety Considerations

I make it a point to use anti spatter sprays in well-ventilated areas. Some sprays contain chemicals that can be harmful if inhaled or if they come into contact with skin. Wearing gloves and protective eyewear while applying the spray has helped me avoid irritation. Also, I look for sprays that have clear safety instructions and MSDS (Material Safety Data Sheet) available.

Cost and Quantity

Depending on how often I weld, I choose the size and quantity of anti spatter spray accordingly. Buying in bulk can be more economical if you weld frequently. However, sprays can lose effectiveness over time, so it’s best not to stockpile too much. Balancing cost with shelf life has helped me avoid waste.

Environmental Impact

I’ve become more conscious of the environmental impact of the products I use. Some anti spatter sprays are more eco-friendly, with biodegradable ingredients and minimal volatile organic compounds (VOCs). Considering these options aligns with my goal to reduce my environmental footprint while maintaining good welding practices.

Final Thoughts

Choosing the right anti spatter spray has made a noticeable difference in my welding workflow. It reduces cleanup time, protects my equipment, and improves the overall quality of my welds. By considering the type, application, compatibility, safety, cost, and environmental impact, I found a spray that fits my needs. I recommend taking the time to assess these factors before making your purchase.

Author Profile

-

I’m Janet Taylor, and my journey has been anything but conventional. Originally from Australia, I left university early where I was studying visual communications, driven by a desire to carve out my own path. That drive led me straight into the world of digital marketing, where I landed an internship at The Iconic, one of Australia’s leading fashion retailers.

Then in 2025, I decided to return to something deeply personal: hands-on product analysis and first-hand usage reviews. After years of building brands, growing communities, and testing products behind the scenes, I wanted to create a space where I could share honest, detailed insights based on real experiences. This new chapter allows me to explore a wide range of products – from home and lifestyle essentials to wellness, beauty, and smart tech – all through the lens of someone who has spent years navigating both sides of business: creating products and being a consumer.

Latest entries

- November 25, 2025Personal RecommendationsWhy I Switched to a 0.2 Tog Sleep Sack: My Personal Experience and Expert Insights on Baby Comfort

- November 25, 2025Personal RecommendationsWhy I Recommend 0-3 Month Onesies: Expert Tips from My Newborn Journey

- November 25, 2025Personal RecommendationsWhy I Trust the 0.5 mL Syringe for My Insulin Needs: A Personal Journey and Expert Insights

- November 25, 2025Personal RecommendationsWhy I Swear by My 0.5 mm Clutch Pencil: An Expert’s Personal Experience